Pyro-GCMS for Petroleum Geochemistry

Our long-term hardware hands on experience and geochemistry background helped us to create highbrow and budgetary solution. We have integrated the classical method and the latest achievements of Pyro-GCMS into one powerful tool

OUR SOLUTION

Single system for multiple applications.

Best-in-Class Pyrolyzer for GCMS

Autosampler automates a continuous analysis of up to 48 samples

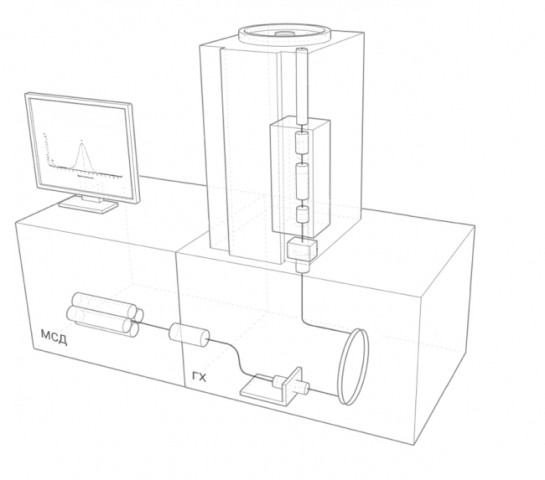

EGA capillary tube for direct connection between the GC injection port and the detector (MSD)

Vent-Free adapter that allows quick column exchange without venting MS to the atmosphere

Software

Best-in-Class Pyrolyzer for GCMS

Autosampler automates a continuous analysis of up to 48 samples

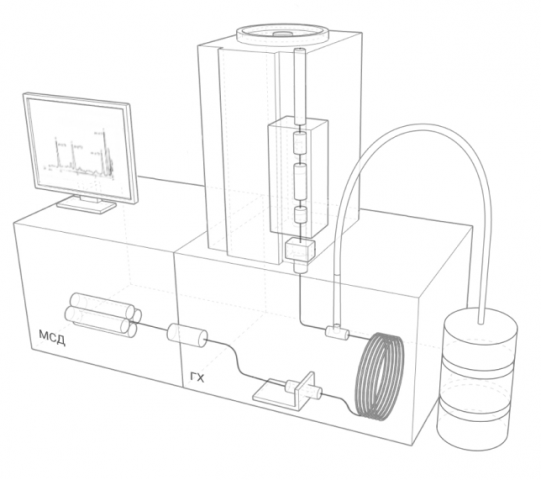

GC column for fast and efficient separation of pyrolysis products corresponding to the S1 peak or S2 peak respectevely

Vent-Free adapter that allows quick column exchange without venting MS to the atmosphere

Software

A cryo-focusing device that traps volatile pyrolysis products. Enable to achive excellent chromatography resolution

Liquid nitrogen container for cryo-focusing device LN2 supply

The EGA-MS mode completely simulates conventional pyrolyzer based on Rock-Eval® approach. Sample placed in stainless steel cup is heated according to a similar conventional pyrolyzer temperature programm. The hydrocarbons released first at the thermal desorption stage (S1 peak) and then during the pyrolysis (S2 peak) are transferred by the carrier gas to the EGA capillary tube heated by the gas chromatograph (GC) and then acquired by the mass-selective detector (MSD) in Scan mode.

The quantitative analysis is performed using the area of the integrated peaks on the EGA pyrogram through the detector response coefficient calculated after standard sample area peaks measurement. The resulting EGA pyrogram is also used to calculate Tmax and hepls for further experiments in other modes. For example, specific ions can indicate sulfur-containing pyrolysis products in order to determinate the structure of the initial sulfur substances, and monitoring the c m/z 44 ion will give information about the amount of organic (S3) and mineral CO2 (S3') produced during pyrolysis of kerogen.

It is performed two-steps test. First, the sample is analyzed by the thermal desorption technique with cryo-focusing and GC separation all released products and then, without removing the sample from the pyrolyzer, we can run the pyrolysis stage, also with the cryo-trapping and chromatography separation of the kerogen thermal cracking products. MSD is operated in Scan/SIM mode. The mode allows you to obtain much more detailed molecular information that is not available on traditional systems. The extensive solvent extraction is not required. For example, a detailed GCMS analysis of the S1 peak will provide information on the distribution of n-alkanes, aromatics, isoprenoids and a number of specific biomarkers. A ratio of combinations of biomarkers yields information on the conditions during deposition, age, maturity, lithology and type of organic matter without long prior extraction.

Using a multi-step analysis of light hydrocarbons composition (C1, С2-С5, С6-С14, C15+) of the S2 peak, you can build the kinetic model of the kerogen transformation..

UNIQUE FEATURES

Accuracy

Py-GCMS allows you to achieve the higher accuracy of the general parameters (S1, S2, S3, and Tmax) than the classical analyzer in a single run and using a single GCMSD channel only.

Easy to operate

No ancillary equipment. You do not need to purchase additional gas generators, compressors, rapid cooling systems of the furnace etc. All you need is the carrier gas (helium).

High throughput

Run time does not exceed 20 minutes. By the customer request a Py-GCMS can be equipped with an automatic cups feeding system. It will reduce the time between analysis and provide for 24 hours a day instrument operation.

The S1 and S2 peaks detaled analysis

In addition to conventional indicators, it is possible to analyze the individual hydrocarbons composition of any thermal zone of pyrolysis in order to determinate biomarkers, for examples, or fulfilment comprehensive study of kerogen kinetic.

Reasonable price

The cost of complete package the is 2 times cheaper at least than the cost of a classic rock pyrolyzer. The ownership cost as well as the cost of single test , is reduced also, due to low investment funds for the instrument purchasing.

Automation switching beetween EGA-MS and Py-GCMS (patented)

We can set up the two-channel analyzer configuration: the first channel is equipped by GC column for the separation of pyrolysis products (Py-GC/MS mode), the second channel is responsible for EGA-MS mode. Switching between channels will be performed automatically by choosing appropriate method in the software.

Versatility, multitasking and large application range

The GCMS can be used for the other samples analysis – hydrocarbon gases, crude oil and its fractions, extracts from the cores, reagents for oilfield chemistry. Pyrolyzer deinstallation is not required. You can also use the pyrolyzer as a true two-stage thermal desorber for oil exploration by passive adsorption and for environmental analysis of soil.

Certified

The solution was certified by the ALL-RUSSIAN RESEARCH INSTITUTE OF METROLOGICAL SERVICE (VNIIMS). Our solution is already operated successfully at many petroleum geochemistry centres that perform as a scientific research and work as CRO for leading oil production companies.